25 May,2020

| Veneer Peeling thickness | 0.8-4.0mm |

| Veneer output speed | 30-90m/Min |

| Power of double roller motor | 7.5kw*2 PCS(Siemens) |

| Power of single roller motor | 7.5kw*1 PC(Siemens) |

| Power of feeding motor | 11kw*1(servo motor) |

| Power of clipper motor | 3.7kw*1(servo motor) |

| Total power | 44.7kw |

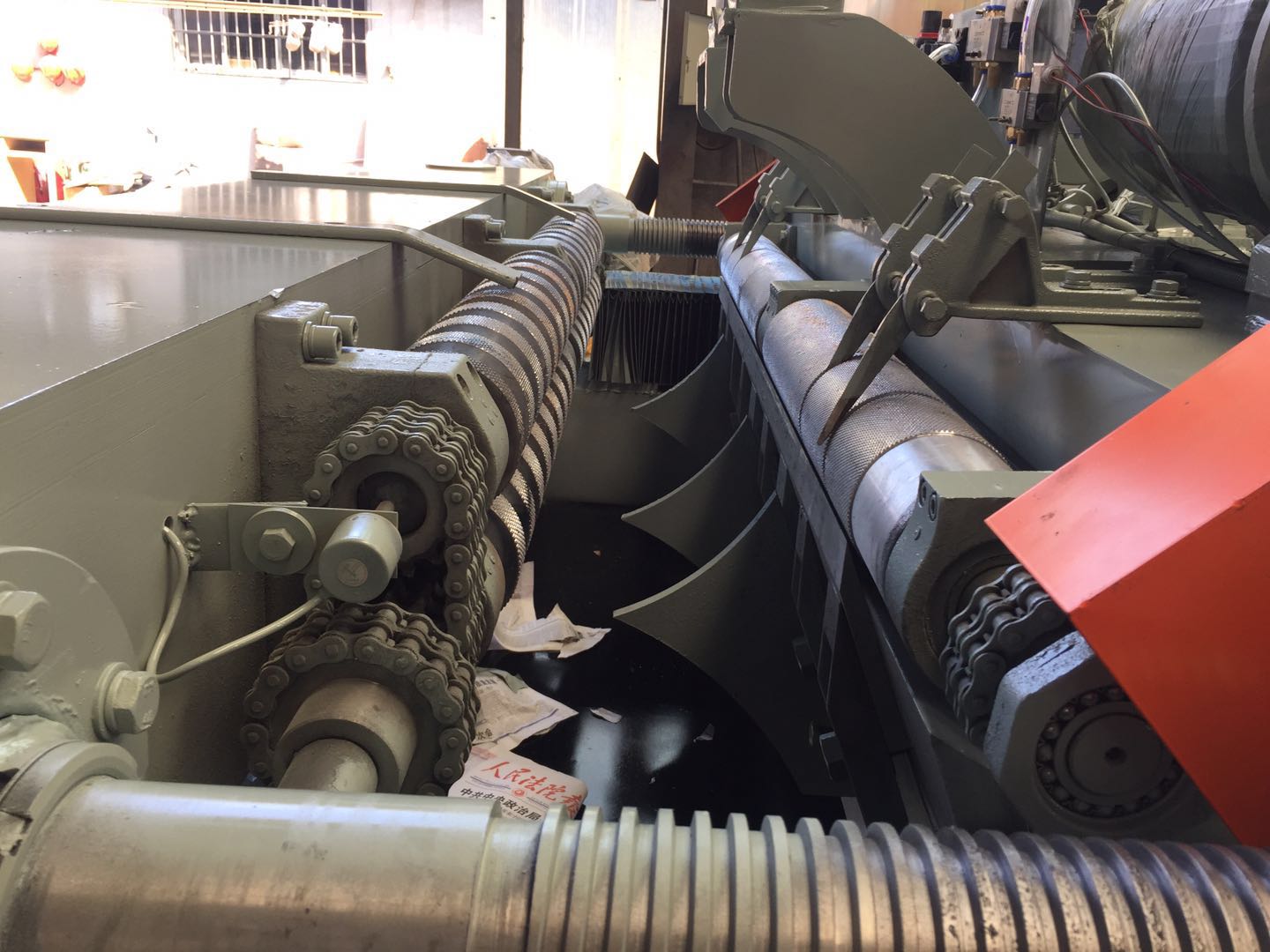

| Roller reducer | R87 Helical gear reducer |

| Diameter of single/double roller | 150mm |

| Min.Last core diameter | 24mm |

| iron board | 4.0mm |

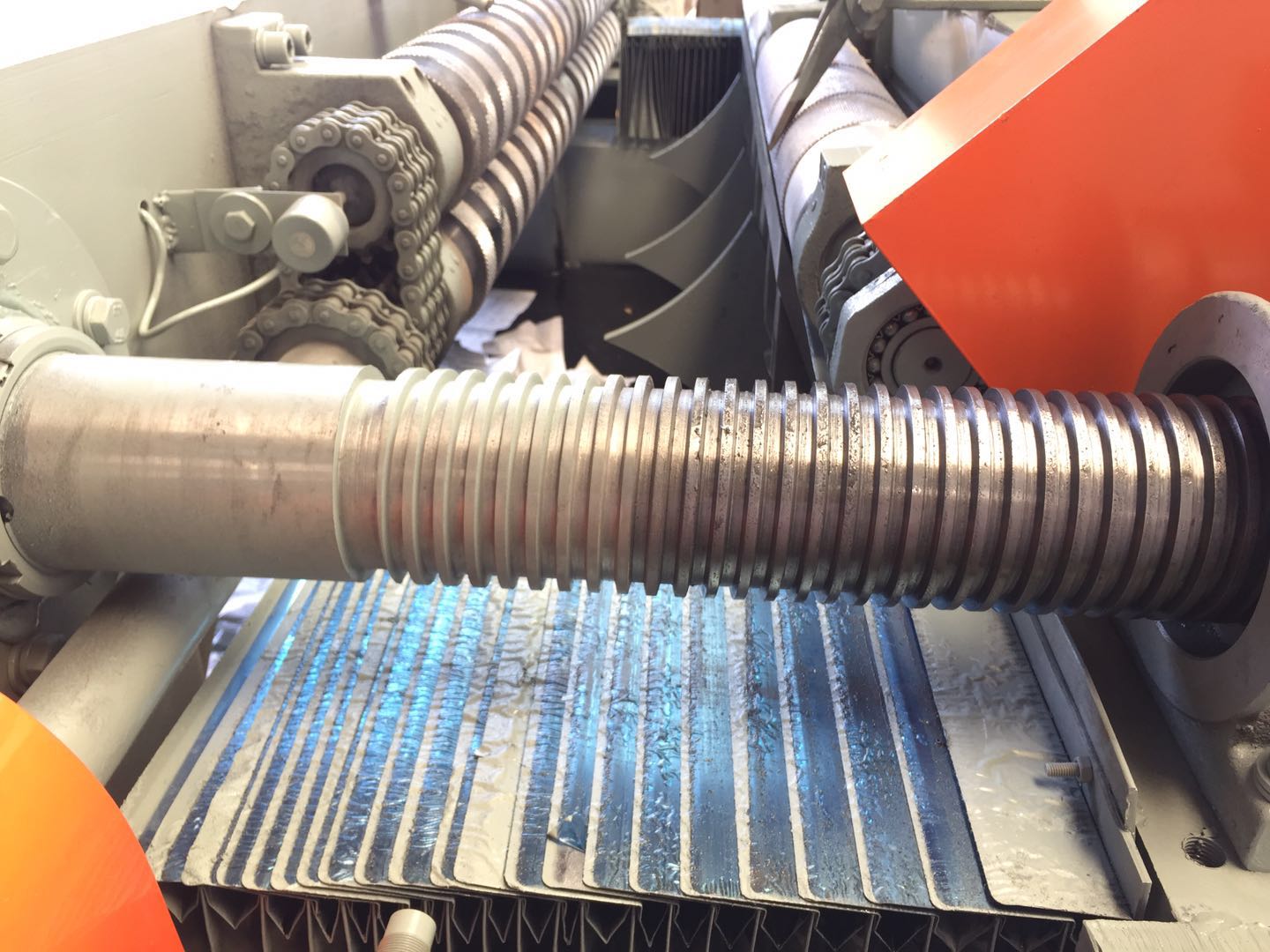

| Diameter of lead screw | 94mm |

| Knife fixing bolt thickness | 24mm |

| Total weight | 6.4T |

1.the main iron frame used with 4.0mm thickness iron boad,the total weight of machine is above 6.4T to make sure machine is stable on process of working

2.the single and double rollers all under plating process to make sure it's hard and durable.

.

3.the 24mm bolt,the machines connected with 24mm bolt tightly,avoid getting loose on process of long time working.

4.the auto-oil systme for machines,no need workers to add oils time by time.

5.the diameter of feeding lead screw is 94mm,bigger than normal.the machines can be used for at least 7 years.

Loading Photos

Factory production process

Feedbacks from customers