03 Jul,2020

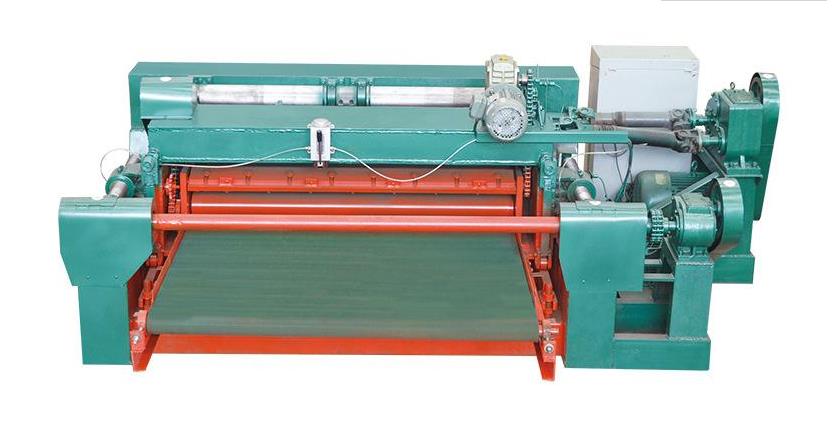

The working speed of the rotary cutting machine is particularly fast and its efficiency is particularly high, but at the same time, it should also be maintained well. For example, before using, it is necessary to check the condition of the safety facilities, to ensure that the components are correctly installed before starting, and to be familiar with the operation of the machine.

Be familiar with the structure and performance parameters of the main rotating chain of the rotary cutting machine, and it is forbidden to use it with super performance. In case of abnormal phenomena, the machine should be shut down immediately to eliminate the fault. If the spindle system with belt drive is used, it is necessary to regularly observe and adjust the tightness of the spindle drive belt of the rotary cutting machine to prevent the loss of rotation caused by belt slip. If the main drive system with hydraulic fork is used, the speed must be changed after the spindle stops. Also prevent all kinds of impurities into the lubricating oil tank, keep the oil clean.

It is also necessary to regularly check the feed stroke switch to ensure its safety and reliability, so as to avoid collision and damage to the machine. It is necessary to clean and maintain the equipment regularly and add lubricating oil to the lubricating parts to ensure the normal operation of the rotary cutting machine.