20 Jul,2020

With the continuous improvement of people's living standards, decoration and building materials industry has also been unprecedented development, but also the production of wood-based panels, plywood rotary cutting machine equipment put forward new requirements.

However, at present, most of the rotary cutting machines used in China are relatively backward, with low degree of automation and low production efficiency. The thickness error of processed plates is large, and the waste of raw materials is serious.

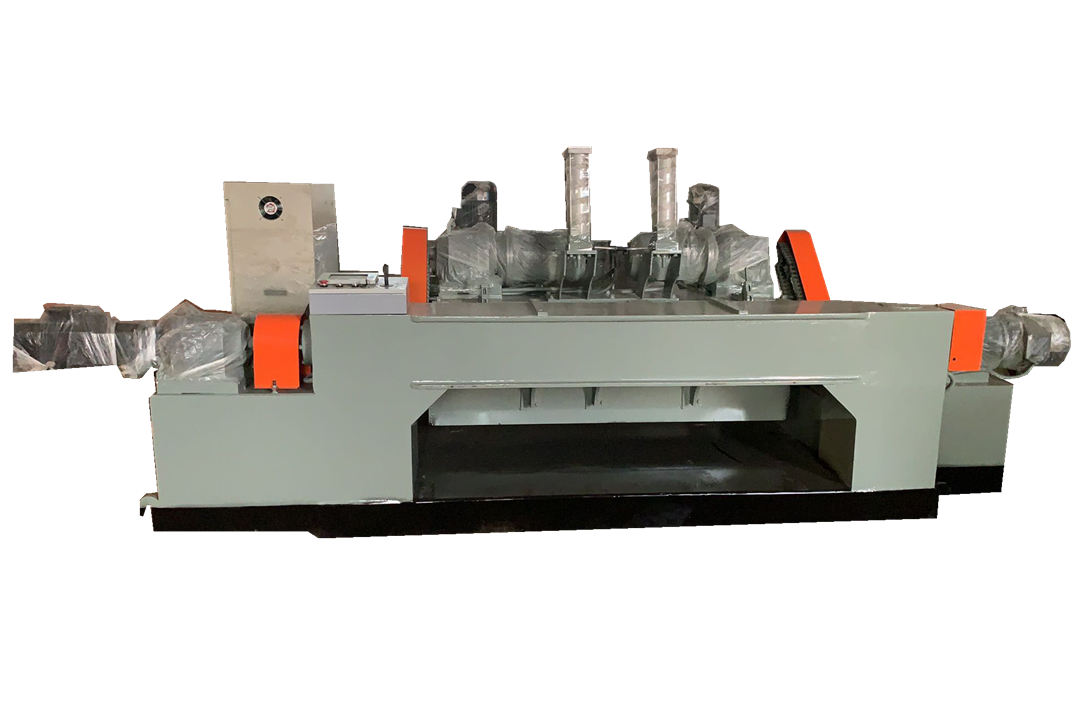

Linyi Guoyu machinery wood rotary cutting machine factory through continuous efforts to develop a new generation of wood rotary cutting machine, the following with the small weaving together to see Linyi Guoyu machinery production of wood rotary cutting machine.

Compared with other rotary cutting machine of Linyi:

1. Stable low-frequency torque characteristics ensure uniform thickness of rotary cutting wood with error less than ± 0.01mm;

2. Making full use of the excellent speed control accuracy, the length error of automatic rotary cutting board is less than ± 20 mm;

3. Good flux weakening control makes the brake performance excellent, meet the requirements of emergency stop and start for 0.1s, and fast forward and reverse switching;

4. The real-time dynamic control makes the wood rotary cutting fully, and the remaining wood diameter is less than 20 mm;

5. The communication function of ke300 inverter is used to realize the communication between frequency converter and PLC;

6. Parameter solidification, simple debugging, supporting dynamic / static self-learning of motor parameters;

7. Good overload capacity and environmental adaptability, high operation reliability;

8. EMC has excellent performance, which can avoid external interference caused by frequency conversion.