26 Nov,2022

Plywood is a composite materials of thin wood layers(which usually called plies) and resins, the inner structures is the plies rotated up to 90 degrees to ensure the strength, then both sides are coated with thin veneers. Plywood can be used to furniture(doors, cabinets),decoration(floor, ceilings, etc),packing and construction,etc.

There are several types of plywood,

1)Softwood plywood: as one of the most common type of plywood, softwood plywood is comprised of softwood core and softwood face/back, such as pine, redwood, larch, fir, ceder.

softwood plywood are used for structural application, because they are flexible, lighter in weight and less dense than most hardwoods

2)hardwood plywood: hardwood is the plywood panels which are made from hardwood face and back (red oak, birch, walnut, maple and many more), while the core is hardwood or softwood. Most Hardwood plywood is made with Formaldehyde free glues which are not moisture resistant and are therefore Interior Grade panels. therefore, hardwood is the best choice for furniture, for it’s durability and strength, which is resistant to warping and bending.

3)Aircraft plywood: aircraft plywood are also called airplane plywood, which is the top grade durable plywood. they are very thin plywood panels made of birch, spruce, Africa mahogany, etc. the minimum thickness is 1.0mm. the aircraft plywood are commonly used in the manufacturing of furniture, instruments, toys, boats, because they are lightweight, tensile, high strength and reliability.

4)Tropical plywood: tropical plywood are made of mixed hardwood species of tropical timber, such as Meranti, Jelutong, Keruing etc, the materials originally from Asia region(Malaysia, Indonesia), and now it’s also from Africa and south America. Due to its density, strength, eveness of layers resistance quality, the tropical plywood panels are commonly used in construction, furniture, base floors and flooring of containers.

5)Exterior plywood: Exterior plywood are waterproof and can withstand outdoor weather conditions, such as strong winds and heavy rain. they are made stronger by adhering layers with phenolic resin, which is waterproof glue, the glue hardens to form a crystalline substance, making the plywood more resistant to moisture and humidity, therefore, the plywood are commonly used for exterior projects.

6)Lumber core plywood:It is 3-ply sandwiched plywood panels, consists of a face and back veneer, then coated with a crossband veneer, the inner core is a edge-glue lumber. the lumber core plywood are usually used for long shelves for their stiffness and screw-holding ability.

7)Marine plywood:Marine plywood is manufactured with durable face and core veneers which has few defects on its surface, it won’t have core gaps even when you cut the sheets. the different plies are bond together with waterproof WBP phenolic glue so it suitable for marine use. It is recommended for any plywood applications where the timber will be directly immersed in water for a period of time such as boat building and other marine activities and construction projects in areas that has lots of rain or subfloor to prevent water and moisture from seeping through it.

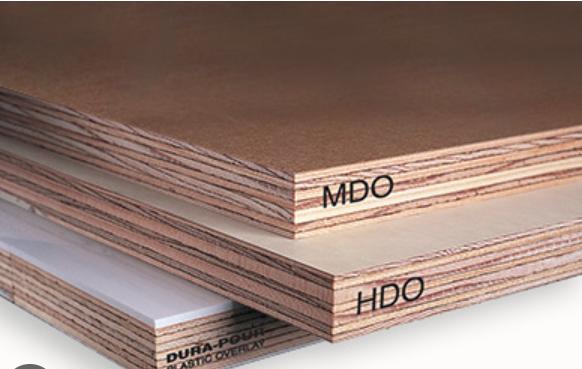

8)Overlaid plywood:Overlaid plywood is manufactured with the same structure of regular sheets, one or both sides are coated with thermosetting resin to make the surface smooth, scratch-resistant and moisture-resistant. The different plies are bond with waterproof glue so the overlaid plywood can withstand moisture for a long time.

There are two types of overlaid plywood: HDO(high-density overlay) and MDO(Medium density overlay). they are commonly used in all applications that are exposed to moisture and weather, such as concrete forming, exterior siding and agricultural industries, etc.

9)Structural plywood:Structural plywood is the engineered wood panel made of many plies hardwood which is heavier and denser than softwood, so they can subjected to heavy loads. Therefore, the structural plywood are commonly used for home construction and buildings, like beams, roof bracing, walls, plywood floorings and other internal structures, sometimes they are also used in packaging.

10)Moisture Resistant plywood:Moisture Resistant plywood is composed of veneer sheets and waterproof glue, therefore, it suitable for use in humid environment.

11)Sanded Plywood: Sanded Plywood is manufactured with face and back veneers which are sanded smoothly in the process of manufacturing, they are often used in cabinetry, furniture, shelving and any other applications where a knot free product is required due to they have smooth and sanded surface without knots.

12)Flexible Plywood:Flexible Plywood are also known as bendy plywood, flexi ply or bendable plywood, is a form of plywood composed of thin plies. The flexible plywood is extremely flexible and easy to bend by hand without breaking into pieces. they are used for creating any type of furniture that should have curved surface. the thickness range from 3mm to 16mm.